Service Process

The equipment that needs to be inspected in wind turbines is usually not accessible to the technical personnel who will carry out the work. In such cases, technical inspections are carried out using various equipment (GE Mentor Visual iQ HD VideoProbe™, Olympus IPLEX GX/GT etc.).

The most important of these is the baroscope inspection method.

Mainly

– Main Bearing, (SKF, FAG, TIMKEN)

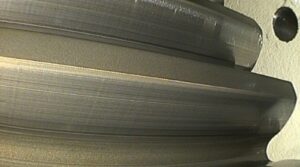

– Gearbox, (Bosch, Rexroth, ZF, Winergy, Eickhoff, Moventas, NGC)

– Generator, (ABB, Siemens, Elin)

– Blade, (TPI, LM, Enercon, GE, Nordex, Siemens, Vestas)

studies are carried out to inspect hard-to-reach areas in the turbine.

As Medwind Enerji, we serve with our internationally experienced technical team and advanced technology devices. At the end of the project, we offer technical analyses in our original report formats requested by your company or as Medwind Enerji, taking into account the quality standards.

Periodic control of wind turbine gearboxes is important. A malfunction in the gearbox may cause damage to other important components of the turbine. In addition, since the replacement of gearboxes carries various operational challenges, an effective inspection is of great importance for planning and minimises turbine downtime. Medwind enerji is your ideal partner for gearbox assessment anywhere in the world.

WHEN SHOULD A GEARBOX INSPECTION BE CARRIED OUT

– Before we start the turbine,

– At the end of the warranty,

– Damage warnings from CMS signals,

– When a root cause is sought,

– If the condition of the gearbox is to be controlled at periodic intervals.

CONTACT US

Contact ınfo

Telephone: +90 543 551 9222

E-mail: info@medwindenerji.com

Adress: Altan Aydın Cad. No:95 Sokak No:53

Kat : 1 Aktepe / Gaziemir / İzmir